Product and Services

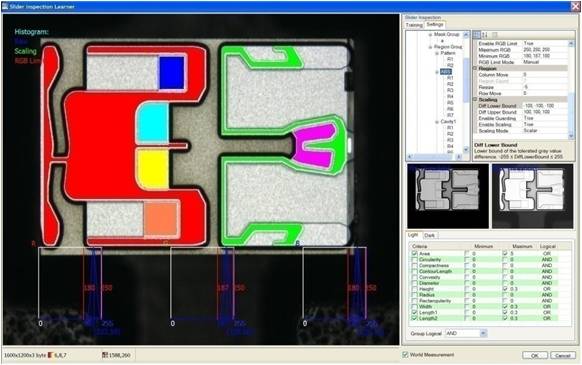

Vision Inspection System

| 1. | Auto Vision Template generation through self-learning from good parts. |

| 2. | Auto compensation for discoloring between lots with same template. |

| 3. | Single Vision Template for ONE product throughout the production. |

| 4. | Auto Template scaling to cater for optics tolerance. |

| 5. | Flexible Parameter Setting and Inspection Rules for each ROI. |

| 6. | Single 'Click' solution to generate a symmetrical mirror product. |

| 7. | Missing/mismatch pattern detection. |

| 8. | Defect size measurement. |

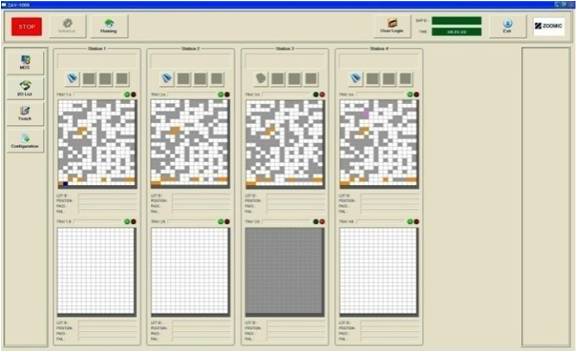

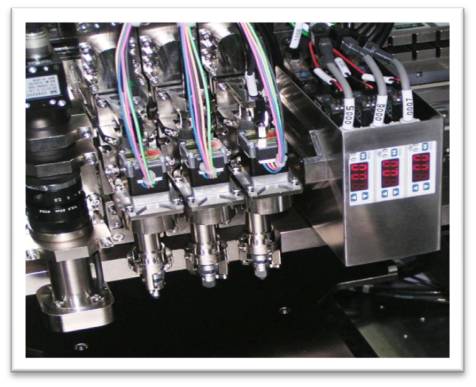

Die Sorter/Pick & Place Machine

| 1. | Real time mapping update. |

| 2. | 100% OCR Accuracy, >99% successful rate |

| 3. | 20um Placing Accuracy. |

| 4. | Data link to Host Server. |

| 5. | SPC report ready. |

Function Test Fixture Design & Manufacturing

| 1. | We provide turnkey solution consist of digital & analogue test and measurement, PC or PLC Base. |

| 2. | System Control, functional test fixtures, product hot test, RF test & etc |

Oven, Chiller’s Temperature and HumidityComputer Monitoring System

Precision & Complicated Tooling Sub-assembly

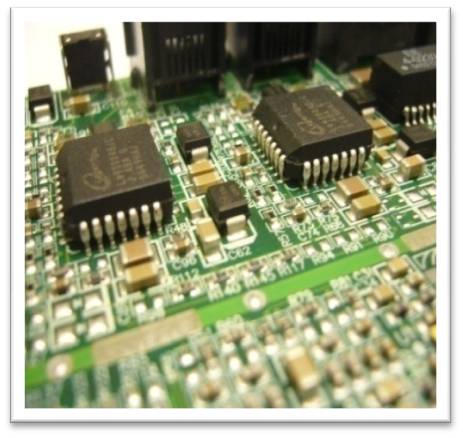

LVHM Printed Circuit Boards Assembly

| 1. | SMT Assembly – Juki CX-1. |

| 2. | Ultra precise Die Attach and SMT Placement. |

| 3. | Chip components (0.5 x 0.25 mm). |

| 4. | Flip-chip attach (tolerance +/-0.02mm). |

LVHM Printed Circuit Boards Assembly & Wire Harness

| 1. | We provide electronics assembly from prototype to medium volume build. |

| 2. | Surface Mount Technology (SMT), Through –Hole and mixed technology. |